刘怀举研究简介

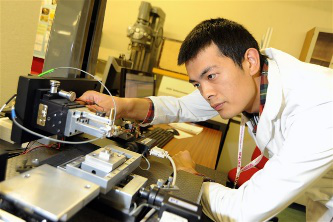

姓名:刘怀举,博士,副教授,博士生导师

地址:重庆沙坪坝重庆大学机械传动国家重点实验室

研究网站:www.gearlab.com.cn

刘怀举,男,1986年10月出生,副教授,博士生导师。2013年获University of Warwick, UK工学博士学位,重庆大学机械传动国家重点实验室专任教师。长期从事传动智能设计、抗疲劳设计制造、复合材料齿轮与强化等方面研究,获教育部科技进步二等奖1项。主持国家自然科学基金项目(课题)3项、装备预研教育部联合基金、重庆市前沿与应用基础研究计划2项、国家博士后科学基金2项、教育部留学回国人员科研启动基金、重庆博士后特别资助、直升机传动技术国防重点实验室开放基金、国家重点实验室自主课题及企业科研项目近30项,参加国家重点研发计划(2018YFB2001300、2018YFB2001600)、国家自然科学基金重点项目(51535012)、国家科技支撑计划(2012BAA01B00)、中国工程院咨询研究重点项目等项目,在齿轮热弹流润滑接触、接触疲劳机理与强化、塑料齿轮等方面取得了原创性成果,构建热弹流润滑接触模型与多轴接触疲劳预测方法,形成基于表面完整性的齿轮疲劳寿命预测技术,创新基于微结构力学的齿轮损伤分析理论,开发基础件动态服役特性与制造加工仿真软件平台,积累了塑料齿轮SN曲线基础数据库,在Appl Surf Sci、Int J Fatigue、Int J Mech Sci、Trib Int、J Tribology、Trib Trans、J Heat Trans、J Vib Cont、Mech Mach Theory等期刊发表SCI论文60余篇,申请/授权专利及软件著作权20余项,长期担任MMT、JOT、TI、IJF等期刊审稿人。参加国际学术会议20余次,担任重庆国际滚动轴承研讨会分会场主席、国际动力传动大会分会场主席,受邀在2019西部摩擦学青年学者论坛作大会报告,指导博士生/硕士生/留学生20余人,指导本科毕设、优异生、实习生40余人,讲授运动学与动力学(英文)、固体力学(英文)、专业外语等研究生/本科生中英文课程5门。

主要研究方向:

l 齿轮抗疲劳设计制造

l 智能传动系统设计

l 机械系统动力学

科研条件:

l 齿轮接触疲劳试验机、弯曲疲劳试验机、齿轮传动综合性能试验台等在内的试验台架

l 光学轮廓仪、X射线残余应力衍射仪、显微硬度仪、扫描电镜、东京应变仪、NI振动仪等检测条件

l Masta、Abaqus、Simpack等专业分析软件平台、有限元二次开发程序集及大型工作站

部分研究论文:

[1] Huaiju Liu*, Wei Wang, Caichao Zhu, Chenxu Jiang, Shihua Yuan, Robert G. Parker, A microstructure sensitive contact fatigue model of a carburized gear, Wear, 2019, 436-437: 203035.

[2] Wei Wang, Huaiju Liu*, Caichao Zhu, Jinyuan Tang, Chenxu Jiang, Evaluation of contact fatigue risk of a wind turbine carburized gear considering gradients of mechanical properties, Friction, 2019.

[3] Haifeng He, Huaiju Liu,* Caichao Zhu, Jinyuan Tang, Study on the gear fatigue behavior considering the effect of residual stress based on the continuum damage approach, Engineering Failure Analysis, 2019, 104: 531-544.

[4] Ye Zhou, Caichao Zhu*, Benjamin Gould, Nicholaos G. Demas, Huaiju Liu, Aaron C. Greco, The effect of contact severity on micropitting: Simulation and experiments, Tribology International, 2019, 138: 463-472.

[5] Qinjie Lin, Huaiju Liu*, Caichao Zhu, Robert Parker, Investigation on the effect of shot peening coverage on the surface integrity, Applied Surface Science, 2019, 489: 66-72.

[6] Boyu Zhang, Huaiju Liu*, Caichao Zhu, Zhengminqing Li, Numerical simulation of competing mechanism between pitting and micro-pitting of a wind turbine gear considering surface roughness, Engineering Failure Analysis, 2019, 104: 1-12.

[7] Boyu Zhang, Huaiju Liu*, Houyi Bai, Caichao Zhu, Wei Wu, Ratchetting-multiaxial fatigue damage analysis in gear rolling contact considering tooth surface roughness, Wear, 2019, 428-429: 137-146.

[8] Peitang Wei*, Huaiju Liu, Caichao Zhu, Haifeng He. Continuous damage-based Voronoi finite element analysis of contact fatigue of a wind turbine gear. Proc IMechE Part J: J Engineering Tribology, 2019, 233, 10: 1483-1495.

[9] Xiangyang Xu*, Xupeng Fan, Peng Diao, Huaiju Liu, An investigation on the influence of modification parameters on transmission characteristics of planetary gear system, Journal of Mechanical Science and Technology, 2019, 33(7): 3105-3114.

[10] Peitang Wei*, Hao Zhou, Huaiju Liu, Caichao Zhu, Wei Wang, Guanyu Deng, Modeling of contact fatigue damage behavior of a wind turbine carburized gear considering its mechanical properties and microstructure gradients, International Journal of Mechanical Sciences, 2019, 156: 283-296.

[11] Zehua Lu, Huaiju Liu*, Caichao Zhu, Hailan Song, Guoda Yu, Identification of failure modes of a PEEK-steel gear pair under lubrication, International Journal of Fatigue, 2019, 125: 342-348.

[12] Wei Wang, Huaiju Liu*, Caichao Zhu, Peitang Wei, Wei Wu, Micromechanical analysis of gear fatigue-ratcheting damage considering the phase state and inclusion, Tribology International, 2019, 136: 182-195.

[13] Haifeng He, Huaiju Liu*, Caichao Zhu, Analysis on fatigue crack initiation of a wind turbine gear considering load sequence effect, International Journal of Damage Mechanics, 2019, doi.org/10.1177/1056789519836272.

[14] Huaiju Liu*, Heli Liu, Caichao Zhu, Ye Zhou, A review on micropitting studies of steel gears, Coatings, 2019, 9(1): 42.

[15] Heli Liu, Huaiju Liu*, Caichao Zhu, Zhangdong Sun, Houyi Bai, Study on contact fatigue of a wind turbine gear pair considering surface roughness, Friction, 2019, doi.org/10.1007/s40544-019-0277-3.

[16] Zonglin Gu, Caichao Zhu*, Huaiju Liu, Xuesong Du, A comparative study of tribological performance of helical gear pair with various types of tooth surface finishing, Industrial Lubrication and Tribology, 2019, 71(3): 474-485.

[17] Wei Wang, Huaiju Liu*, Caichao Zhu, Zhangdong Sun, Evaluation of contact fatigue life of a wind turbine carburized gear considering gradients of mechanical properties. International Journal of Damage Mechanics, 2019, 28: 1170-1190.

[18] Wei Wang, Huaiju Liu*, Caichao Zhu, Peitang Wei, Jinyuan Tang, Effects of microstructure on rolling contact fatigue of a wind turbine gear based on crystal plasticity modeling, International Journal of Fatigue, 120: 73-86.

[19] Wei Wang, Huaiju Liu,* Caichao Zhu, Effect of the residual stress on contact fatigue of a wind turbine carburized gear with multiaxial fatigue criteria. International Journal of Mechanical Sciences, 2019, 151: 263-273.

[20] Huaiju Liu*, Heli Liu, Caichao Zhu, Peitang Wei, Jinyuan Tang, Tribological behaviour of coated spur gear pairs with tooth surface roughness. Friction, 2019, 7(2): 117-128.